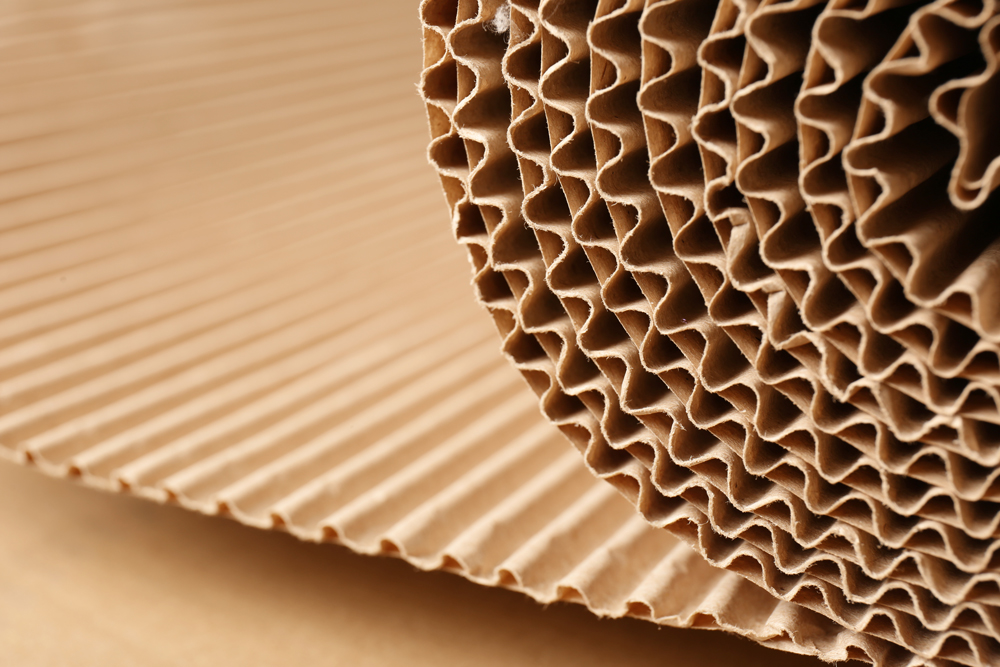

Corrugated Containers are a Recycling Marvel in Society Today

Posted on: June 7th, 2021

During the heart of the Covid-19 pandemic, online shopping and packaged deliveries soared – so did the amount of waste being generated and left at the curb for municipal collection across the United States. Corrugated containers were the biggest culprit as boxes seemed to be a never-ending occurrence overflowing from the limits of recycling bins.

But thankfully, the story of corrugated containers has a happy ending.

Corrugated containers are currently the most recycled material in the United States. In 2018, 96% of all corrugated containers produced were not only recovered and prevented from entering landfills, but much of that material was used to make new products. Not even paper can make such a remarkable claim.

Recycling corrugate was not always as high as it is today. Since the introduction of the corrugated recycles symbol back in 1993, the recovery rate has been climbing. Combine that with dramatic increases in E-Commerce and the need for sustainable practices for corrugated containers virtually exploded.

Recycling corrugate can even be a revenue producer for large organizations, for OCC (Old Corrugated Containers) are incredibly valuable to paper mills and other manufacturers both foreign and domestic.

As of 2018, more than 50% of the recovered corrugate was currently used to make containerboard for more corrugated boxes. Another 10.4% was used to make boxboard for items such as cereal boxes, and some 34% was exported, with global demand for OCC growing steadily.

While almost everyone (businesses and consumers alike) contributes to the corrugated container recycling process, few understand what goes into it.

Once collected, bales of OCC are put into what is called a repulper – a large blender that mixes with water until it becomes a slushy pulp.

Contaminants such as long pieces of rope, string, tape, plastics, and metals are strained out and additional contaminants sink to the bottom.

Poured onto a moving screen, the water drains away (for reuse), and a continuous fiber mat is produced and pressed between rollers to extract additional moisture while drying the product out. It’s then rolled up on reels which weigh between 10-60 tons for use in the creation of new corrugated materials.

Not only are HC’s protective packaging, consumer products, and growing containers produced similarly, we reuse corrugated waste from our facilities across North America to produce our products creating our own little circular economy.

As society continues to shop online and more organizations search for more sustainable solutions for their protective packaging, corrugates recoverability rate will continue to remain high.

For more information on HC’s sustainable fiber solutions, click here.

Sustainable Solutions

Learn how HC uses corrugates in the production of their protective packaging, consumer products, and growing containers.

Why Fiber? ☰ Menu

☰ Menu